What is the s-Camshaft?

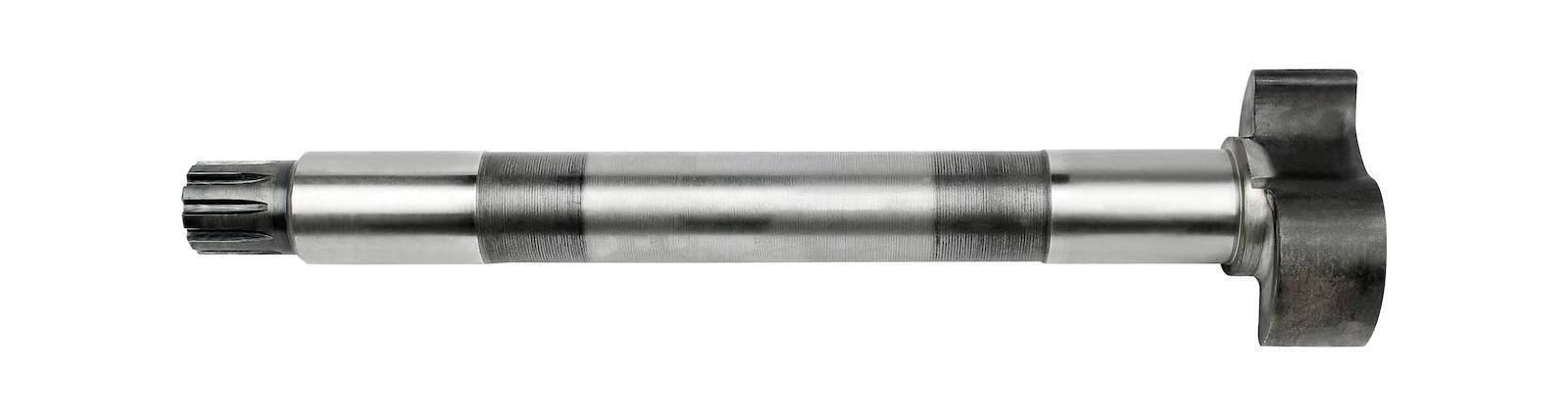

CNC turning process at the S-Camshaft production stages, precision surface processing operation is performed according to RA 1,6 tolerances. S-Camshaft body and S form are processed parallel to each other in the horizontal machining center. Hobbing teeth are opened at the desired DIN tolerances on the horizontal milling machine. Hardening process is performed at the desired Rockwell hardness value in the induction machines we designed.

After the hardening operation of the S-Camshaft, it is painted in the desired colors in our electro static powder paint facility against corrosion and rust.After painting, the grinding process is performed at the desired percentage tolerances on the CNC cylindrical grinding machine and the product is ready for sale. S-Camshaft can be produced according to any desired length and S form.

S-Camshaft, is an integral component of our strategy, minimizing the maintenance cost of vehicles by not only making each brake component more rigid, but better adapting to the relevant parts.

Some of the unique features of S-Camshafts are:

- Higher grade steels

- Machined S-cam head surface

- Heat treated heads

- Stone floor

S-Camshafts Can Withstand Harsh Conditions

Premature shaft wear is a leading cause of premature brake failure and uneven braking. S-Camshafts are made to the highest standards. We use premium high-carbon HRC 45 tool grade steel for our s-camshaft brake parts, which include the journal and cam head. This high-quality steel can withstand even the harshest cold conditions found in the north of Canada and has been proven to last longer in milder road conditions.

Tighter Tolerances for Better Braking

After our S-Camshaft heads are forged, they are precisely cut at both the spline and cam end to achieve 0.050 inches tighter tolerances than the unmachined spindle heads that support stable braking. Spindle heads that are not precision milled can have a variation of up to 0.050 inches between spindle lobes, resulting in uneven braking and ultimately uneven brake wear.

Longer Life and Maximum Brake Efficiency

S-Camshaft heads, journals and keys are heat treated above 1000˚F (560˚C) until reaching the standard OE hardness of HRC60. Properly hardened S-camshaft heads reduce wear and extend cam life.

Reduced Wear

To perfect our S-Camshafts, they are stone-ground to a thin RA16 coating to provide tighter tolerances and minimize shaft bushing wear, compatible with every test.

The driver of the vehicle, powered by hydraulic or air power, presses the brake pedal, which sends power to the diaphragm. This diaphragm sends the motion to a push rod that rotates the shaft connected to the S-cam. As the S-Camshaft rotates, the two symmetrical brake pads are forced into the brake drum until the pressure is released and the brake pads return to their resting positions.

Since the S-Camshaft principle is based only on a rotating shaft, it makes the brakes of large vehicles more compact and less moving parts. In general, a tractor trailer requires more brakes than a typical vehicle, so it is essential to make brakes as simple and cost-effective as possible.

S-Camshafts are very effective at retaining brakes because the more the brake pad wears, the more the S-Camshaft rotates, causing the pads to move further. As the lobes on the S-Camshaft increase in radius as they rotate, the linear motion of the brake pads increases. Of course, you want to adjust your brakes regularly to make sure there is no slack in your brake system and that your brakes are responsive.

S-Camshafts are unidirectional. S-Camshaft is divided into two as left and S-Camshaft right.

What is Brake Adjuster?

Brake Adjusters are a part of a brake mechanism that transmits the thrust force of the brake chamber to the S-camshaft and provides an opening movement to the brake shoes and performs the braking of the vehicle with the friction of the pads to the drum in the brake systems of vehicles carrying heavy loads.

What Is The Function of The Brake Adjuster?

In brake systems operating with Brake adjuster air pressure systems, the air filled into the bellows when the brake pedal is pressed activates the brake ratchet with the support of the bellows shaft in the range of 6-8 bars. At the same time, with the forward circular movement of the S-Camshaft, the brake shoes are opened and the pads rub against the drum, thus the brake is applied.

With the movement of the S-Camshaft, the spring is activated inside the brake shoes. When the force applied to the brake pedal is released, this spring takes its previous form and prevents the brake pads from rubbing against the drum.

Due to the wear of the lining over time, the gap between the drum and the drum increases and it is not enough to brake without danger. Here, the automatic brake adjuster enters the circuit and automatically closes the gap between the lining and the drum without wearing it, and provides an unchangeable and safe braking. Since this feature is not available in manual brake adjuster, the adjustment of the brake adjuster should be done periodically by authorized service personnel.

Automatic brake adjuster adjust the stroke of the brake chamber to keep the stroke short, so the air consumption used is less. Increases the service life of the compressor, brake chambers and other air brake parts. Braking is quick and safe, and caliper braking on full wheels. Brake adjuster of the vehicle is provided by automatic brake ratchet.

The automatic brake adjuster is the mirror of the entire brake system. It performs its adjustment by over-setting a possible stretch or runout in the brake system.

The stretch in the S-Camshaft is also a reason for the automatic brake adjuster to set up more.

Especially in Trailer, Jumbo and pilot axles, automatic brake adjuster are installed more because of the long life of the S-Camshaft and its stretching. In such a problem, in order to get more benefit from the automatic brake ratchet, the stretching of the S-Camshaft should be taken clearly.

S-Camshaft Models;

- GIGANT-SAE-SMB - S-Camshaft

- MAN - S-Camshaft

- MERCEDES - S-Camshaft

- MERITOR-ROR - S-Camshaft

- RENAULT - S-Camshaft

- SAF HOLLAND - S-Camshaft

- SCANIA - S-Camshaft

- VOLVO - S-Camshaft